A commercial freezer is one of the most vital pieces of equipment in any food business. When it fails, the impact is immediate and costly. Spoiled inventory, lost revenue, and unhappy customers are just the beginning. That’s why it’s essential to recognize the early signs of failure and take prompt action.

Freezers work hard around the clock to maintain consistent temperatures. Any disruption in performance puts food safety and quality at risk. With a robust commercial refrigeration system, your business operates smoothly and avoids unexpected breakdowns. This article highlights common reasons commercial freezers fail and explains how proper repairs restore reliable operation.

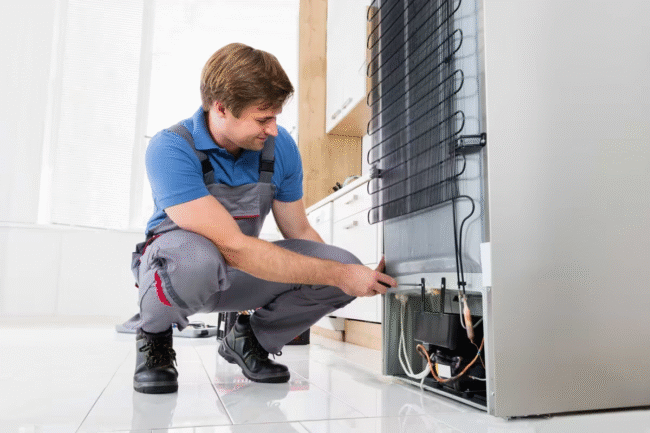

Blocked or Dirty Condenser Coils

The condenser coil releases heat from the freezer into the surrounding air. If this coil becomes dirty, the unit struggles to cool effectively. Dust and grease buildup can restrict airflow, causing the compressor to work harder than necessary. This leads to higher energy use and eventual failure.

Routine cleaning can prevent these issues. A technician can remove dirt and inspect the coil for damage. Replacing a clogged coil is more expensive than cleaning it regularly. Maintenance like this also helps spot signs of wear early.

Thermostat or Sensor Malfunctions

The thermostat controls the freezer’s internal temperature. When it fails, your unit may run continuously or shut off prematurely. This results in temperatures that are too warm or too cold. Spoiled food or frost buildup can follow.

A faulty sensor gives incorrect readings, sending the wrong signals to the control board. Technicians can test, replace, and recalibrate the unit’s damaged sensors. These small components play a significant role in your freezer’s performance and must be accurate to function correctly.

Refrigerant Leaks or Pressure Imbalance

Refrigerant is the chemical that cools the air inside the freezer. If there’s a leak, cooling power drops significantly. A low refrigerant charge also puts stress on the compressor and fan motor. These issues worsen if not addressed promptly.

Leaks can come from cracked lines or worn fittings. A trained technician uses specialized tools to detect and seal them. This helps restore complete cooling and reduces energy use. Ignoring refrigerant problems can shorten your system’s lifespan.

Door Seal or Gasket Damage

The gasket or door seal prevents cold air from entering and warm air from escaping. If it’s torn, loose, or cracked, the unit has to work harder to maintain a stable temperature. Warm air leaks inside, leading to frost and inconsistent cooling.

Replacing the seal is a simple repair that brings quick results. A proper seal helps save energy and maintains stable internal temperatures. Technicians can inspect the gasket to ensure the door closes tightly. This small fix can prevent larger cooling problems and extend the life of your equipment.

Electrical or Control Board Failures

Your freezer relies on a control board to manage cooling cycles and settings. When this board malfunctions, it can disrupt the entire operation of the unit. Electrical issues, such as short circuits, blown fuses, or faulty wiring, can also prevent the system from running.

These problems often show up as power loss, display errors, or inconsistent cycling. A professional will test the control board and electrical lines to ensure they are functioning correctly. Catching these issues early helps avoid major repairs or the need for a complete system replacement.

Freezer breakdowns can be frustrating and expensive, but many issues have simple solutions. Quick repairs prevent further damage and restore performance. Regular inspections and prompt repairs ensure commercial refrigeration systems operate smoothly and prevent costly surprises. A dependable system ensures your food is safe and your kitchen runs smoothly.