When you’re working with an aluminum extrusion channel, it’s easy to focus on the profile’s width, height, or shape. But there’s another crucial detail that deserves just as much attention: wall thickness. Often overlooked, wall thickness can determine the structural integrity, cost-effectiveness, and suitability of your aluminum channel for any given project. Whether you’re a DIY builder crafting a frame or a contractor sourcing material for a commercial storefront, understanding wall thickness is key to long-term performance.

What Is Wall Thickness in Aluminum Extrusions?

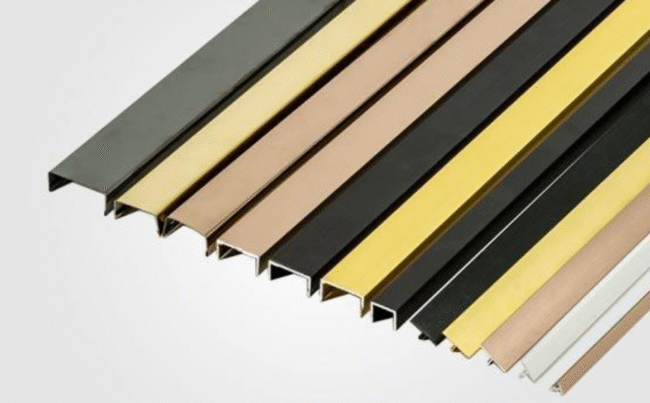

Wall thickness in aluminum channel extrusions refers to the distance between the inner and outer surfaces of the metal profile. It’s essentially the “meat” of the channel—the material that holds it all together. Standard extrusions like U-channels, C-channels, and Z-channels often come with varying wall thicknesses depending on the intended use. This specification influences everything from weight and strength to thermal performance and cost.

Why Wall Thickness Matters

1. Structural Strength

The thicker the wall, the more stress an aluminum channel can withstand. This is critical in load-bearing applications like shelving systems, construction frames, or support brackets. Thin-walled extrusions might look similar, but under pressure, they’re far more likely to bend, buckle, or warp.

2. Durability and Resistance

Thicker channels provide better resistance to dents, impacts, and wear. In outdoor or industrial environments where aluminum is exposed to vibration, moisture, or debris, the added durability can extend the lifespan of the product by years.

3. Fabrication Flexibility

Wall thickness also affects how easily a channel can be cut, drilled, or welded. Thicker materials allow for more aggressive machining, while thinner profiles may require special handling to avoid deformation.

4. Weight and Cost Trade-Offs

Heavier wall sections naturally use more material, which increases both weight and cost. This isn’t necessarily a downside—for some structural uses, it’s a must. But for lightweight builds, like decorative trims or enclosures, thinner walls may be more appropriate and cost-effective.

5. Thermal and Electrical Properties

Wall thickness can influence a channel’s ability to dissipate heat or conduct electricity. In electronics enclosures or LED fixtures, this becomes an important design consideration.

Applications by Thickness Category

- Thin-Wall Channels (≤1/16″): Ideal for interior trims, light framing, and decorative accents. Not suited for structural use.

- Medium-Wall Channels (1/16″ to 1/8″): Great for residential framing, modular furniture, and lightweight mechanical applications.

- Thick-Wall Channels (≥1/8″): Best for load-bearing frameworks, heavy-duty shelving, and commercial-grade systems.

Industry Standards and Precision Tolerances

Manufacturers often adhere to ASTM B221 or similar standards, which specify dimensional tolerances and ensure consistency in production. If your application demands tight fits or high strength, these standards help you choose a supplier with reliable quality.

It’s also worth noting that aluminum extrusions can be custom-made to your specifications. While off-the-shelf options cover many common needs, custom profiles allow you to fine-tune wall thickness, alloy composition, and shape to meet unique project requirements.

Real-World Case Studies

In one commercial solar project, Bonnell Aluminum worked with engineers to thicken the wall sections of support struts. The added thickness improved load distribution and helped the installation pass regional wind load requirements.

Hydro Extrusions reported a product recall on lightweight electric vehicle enclosures due to inadequate wall thickness in structural channels. A simple redesign to a slightly thicker profile corrected the issue and passed fatigue testing.

Choosing the Right Thickness for Your Project

When selecting wall thickness, ask yourself the following:

- What kind of load will this channel support?

- Will it be exposed to harsh weather or physical impact?

- How will it be joined or machined?

- Do aesthetics or weight matter more than structural integrity?

Many designers rely on CAD tools and finite element analysis (FEA) software to simulate stresses before committing to a particular thickness. For those without access to such tools, consult your aluminum supplier or structural engineer.

Sustainability and Material Efficiency

Choosing the right wall thickness isn’t just about strength or cost—it also affects your project’s sustainability footprint. Thinner walls reduce raw material usage, lowering carbon emissions during production and transport. However, overly thin channels that require frequent replacement or reinforcement may end up costing more environmentally in the long run.

Extruded aluminum is 100% recyclable, and many manufacturers incorporate recycled material into their products. Still, selecting the correct wall thickness from the start reduces waste and promotes responsible sourcing.

Final Buying Tips

- Match Thickness to Load: Don’t underbuild structural elements.

- Review Standards: Check for ASTM or ISO compliance.

- Source Responsibly: Choose suppliers with transparent material specs.

- Consider Custom Extrusions: They may offer better long-term value.

- Double-Check Tolerances: Especially if the channel fits into a larger system.

Conclusion

Wall thickness might not be the flashiest spec on a cut sheet, but it’s arguably one of the most important. It dictates strength, durability, machinability, and sustainability. So next time you’re evaluating aluminum channel extrusions, take a second look at the wall. It might just be the difference between a project that lasts and one that fails.